specification

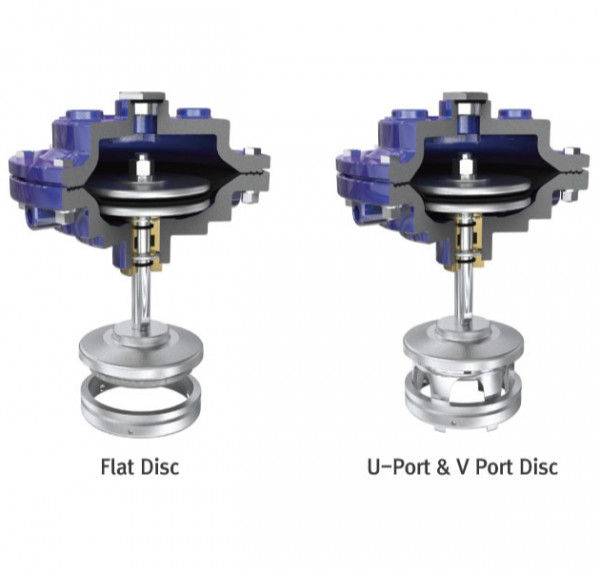

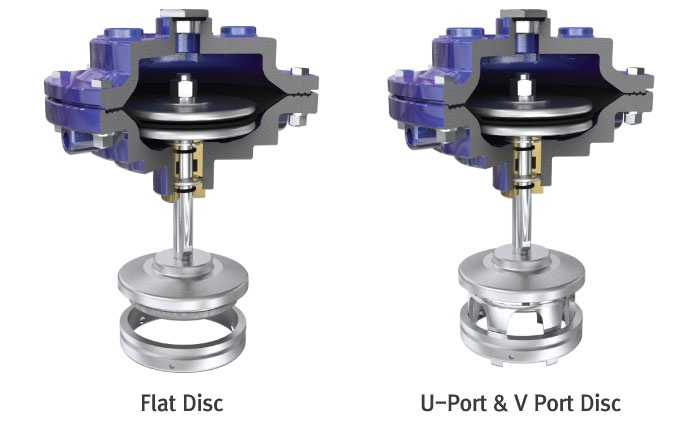

There are a total of 3 types of discs provided by Baram, each with a different cavitation index.

When each disc is used, the recommended decompression ratio and maximum decompression ratio are as follows.

| item | Recommended decompression ratio | maximum decompression ratio | note |

| Flat Disc | 3 : 1 | 4 : 1 | No flow loss |

| U-Port Disc | 4 : 1 | 5 : 1 | About 30% of flow loss |

| V-Port Disc | 5 : 1 | 6:1 | About 50% of flow loss |

When the pressure reduction ratio is large or the flow rate is high, when the valve is operated with the disk almost closed, a sudden pressure drop occurs due to the increase in the flow rate in the portion passing through the seat. At this time, when the pressure drops below the saturated vapor pressure of water, bubbles are generated.

1) Noise and vibration: When the decompression ratio is large, the main cause of noise and vibration is cavitation. This means that when the generated bubbles pass through the sheet and the pressure is higher than the saturated steam pressure, the generated bubbles do not disappear naturally, but burst by the surrounding water pressure. At this time, according to the rapid reduction of the bubble volume, the local pressure is instantaneously raised to a very high value to generate a shock wave and damage the valve surface and the pipe surface.

2) Cavitation corrosion: Corrosion proceeds in a form of pitting erosion around the place where cavitation occurs, and it is not corrosion by electric charge but corrosion by shock wave. Do.